Printed Nike Smoke

3D printing allows us to produce much more detailed parts for scale modeling. Even for relaxed semi-scale modelers, it allows us to add a richness of detail unavailable from HPR kits and difficult to make with other techniques.

However, 3D-printed parts are not yet widely accepted for high-power rocketry because of the wide variance of results, uncertainty about the mechanical properties and unfamiliarity. 3D printing is widely used in model rocketry, where strength is not such an issue, but is still (as of 2023) rare in HPR.

What could I do but give it a try myself? The Nike-Smoke is a perennial favorite, plus there is a lot of detail in the fin can and nose which doesn't usually make it into models. This is the sort of thing that cries out for 3D printing.

After starting this project, I got interesting in testing the mechanical properties of 3D printed components, which resulted in this article: Printed Components.

The Pictures

As always with 3D printing, it took multiple iterations to dial in all parts, but the extra detail is a nice touch, even if the surface finish isn't great.

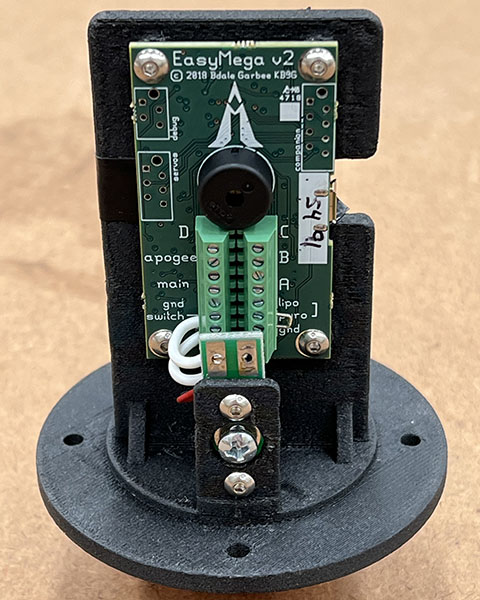

3D printing is particularly nice for electronics bays, where you can create something custom that fits everything perfectly.

The Design

Since this was to be an HPR rocket, I knew I wanted a 54mm MMT. I also wanted to print the fin can as a single unit on my new (at the time) Bambu Lab X1C. The printable volume (250mm³) limited the fin can size and so I chose a 3" airframe (19% scale). The size also required me to print the nose in 3 sections.

As always, the overall drawing is available, althugh there's not much to it. Since this is 3D-printed, here are the various STL files (also posted on Thingiverse):

These are all designed to fit Giant Leap flexible phenolic tubing (3" airframe and coupler).

The components were printed with ABS at 50% infill. The avbay was printed with PETG-CF at 50% infill. All filament was purchased from Bambu Lab.

Components

Above are all the components. Note that I ended up using a different fin can, printed in three colors, but more on that below.

In order to have maximum flexibility in motor selection, I decided to keep this rocket single-deployment with the avionics in the nose cone. That means an entirely open body. Then why so many tubes?

I wanted the printed fin can to taper down to the OD of the airframe, but not be slid over it. This meant using a coupler and resulted in a aft end assmebly that slid both into the fin can and into the airframe tube. The two centering rings are different because the aft one fits inside the coupler and the forward one inside the airframe tube.

Because the parts were all printed from ABS, normal epoxy bonds were used. Here is the forward CR bonded to the MMT with AeroPoxy ES6209.

I'm also taking advantage of the ability to print much more complex shapes to create a CR that is much thicker than a plywood one would be, but with half its thickness lightened and stiffened with ribs instead of being printed solid.

Nose Cone

The glory of the Nike-Smoke is its nose cone. Not only is the most prominent part of the rocket, it also has the characteristic bulge near the base. In addition, it has patches near the bulge and subtler details all the way up to the cylindrical tip where the actual smoke was ejected.

Because of printer limitations, I had to print the nose in three sections, but was of course able to design integrated couplers between them. One of the breaks was aligned with a prototype detail to hide it.

Fin Can

The Nike fin can is also extremely distinctive. I was able to take advantage of 3D printing to add more details to the profile. Of course there is even more one could do, such as the launch rails and bolt heads.

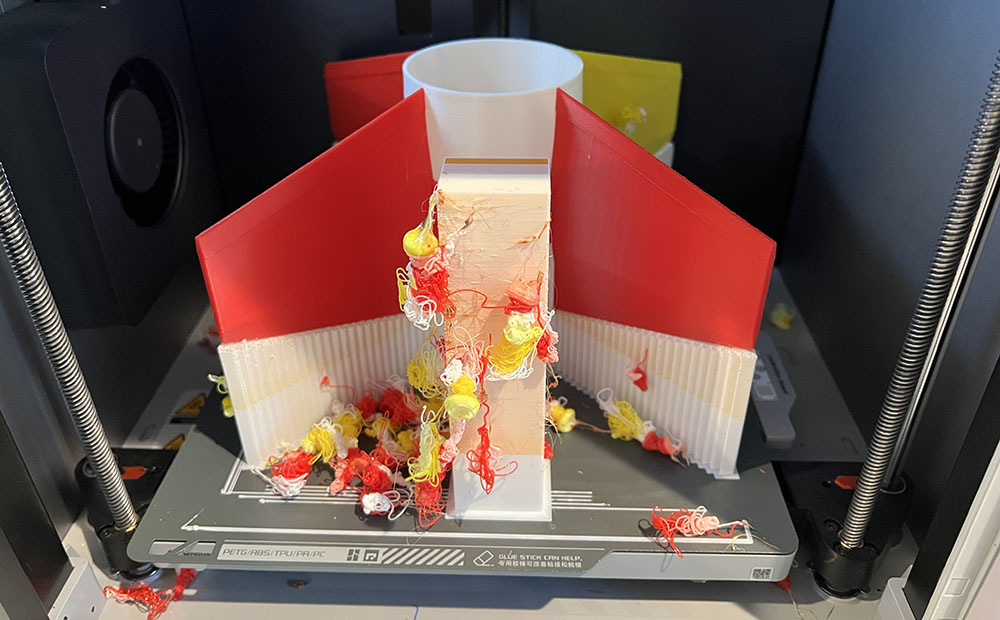

In the photos above, you see a white fin can, which is what I printed while tuning the design. But for the final print, I took advantage of the ability of the Bambu Lab X1C to print multiple colors.

Because the X1C has only a single extruder, it needs to purge filament for each color change, resulting in a huge amount of waste. (As one review put it: "it poops a lot.")

But even so, the result is great and doesn't require painting!