Hybrid Motors

Want to try something different from the standard ammonium perchlorate (solid fuel) motors? Hybrids offer some nice advantages over solid fuel motors:

- easy to set up (just screw the fuel grain into the motor)

- non-explosive (no LEUP required to store or use

- no igniters to fool with (requires separate launch hardware)

- inexpensive (a Hypertek J reload costs about $20)

- no messy clean-up

The motors fit into standard 54mm motor mount tubes. However, there is no delay-based ejection charge with hybrids so an altimeter or other recovery system system must be used. (See my Aurora rocket for retro-fit altimeter.)

Hybrid motors are currently made by Hypertek and Aerotech. Aerotech even has assembly and operation instructions on-line. See below for information on Hypertek products.

My first attempt with Hybrid motors (at ROC-stock on June 14, 1998) was unencouraging. My Aurora was a loss due to some problem with the preparation of the hybrid system. The people helping me assured me it was an unusual failure, perhaps related to the high heat, but we never discovered the cause of the problem.

Hypertek System

Two years after Hypertek flew the world's first N2O Hybrid rocket and following one year of beta testing, Tripoli Motor Testing has approved Hypertek hybrids for consumer use in High Power Rocketry. The Hypertek hybrid motor was developed as a high tech, low cost alternative to the ancient technology of solid propellant rocket motors. Hybrid motors have several safety advantages over solids. The fuel and oxidizer are isolated from each other until just before ignition, thus eliminating the requirement for a low explosive permit during transportation and storage of rocket motors. The Hypertek System also uses a remote fill/fire launch system that gives NASA style launch realism as well as a 100% pyrotechnic free ignition.

The Hypertek flight motor consists of three major parts: the oxidizer tank, the injector bell, and the fuel grain. The fuel grain is molded from thermoplastic and has an insert-molded phenolic nozzle. This monolithic grain functions as both the fuel and the combustion chamber. We've eliminated the complicated assembly of a reloadable system by incorporating the fuel, nozzle and motor case into one injection molded component. The fuel grain simply screws onto the injector bell prior to flight and the spent fuel grain is unscrewed and disposed of after each flight. No messy, time consuming clean up operations are required. Typical motor turn around times between flights can be less than 5 minutes. The injector bell has field interchangeable injector orifices for varying the thrust levels to tailor your motor to the needs of your rocket or launch field. There are currently five different orifices available and more on the way.

| The Hypertek flight motor consists of only three major parts: the oxidizer tank, the injector end bell, and the combined fuel grain/combustion chamber (called the "monolithic fuel grain"). |

|

|

The Hypertek fueler/launcher will work with most popular launch stands using 3/8 to 1/2 inch launch rods and handles rockets from 1 1/8 to 6 inches in diameter. |

Technical Specifications:

| Designation | Orifice | Burn Time | Impulse | Full Wt. | Fired Wt. | N2O Wt. | Dia. | Length | |

|---|---|---|---|---|---|---|---|---|---|

| TMT | Manufacturer | (in) | (Sec) | (N-sec) | (lbs) | (lbs) | (lbs) | (in) | (in) |

| J100 | 440-076-J | .076 | 6.7 | 683 | 2.86 | 1.90 | .75 | 2.125 | 24.2 |

| J125 | 440-086-J | .086 | 6.0 | 743 | 2.86 | 1.91 | .75 | 2.125 | 24.2 |

| J145 | 440-098-J | .098 | 5.1 | 743 | 2.86 | 1.92 | .75 | 2.125 | 24.2 |

| J185 | 440-1104 | .110 | 3.6 | 690 | 2.86 | 1.94 | .75 | 2.125 | 24.2 |

| J205 | 440-125-J | .125 | 3.3 | 684 | 2.86 | 1.96 | .75 | 2.125 | 24.2 |

With one motor, different thrust profiles are available by simply changing the injector orifice.

|

The Hypertek System comes with five fuel grains, an injector bell with integral vent tube, three interchangeable orifices for different thrust levels, and oxidizer tank, tie-down straps, and an operations manual. All for $235. |

|

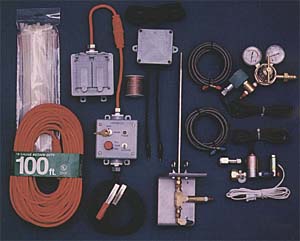

The Fueler/Launcher comes with the launch stem and adjustable mount, all hoses and fittings, N2O and GOX solenoids, dump solenoid, GOX regulator, custom launch control, ignition transformer, operations manual, and instructional video for $550. |