Honest John 1B

This rocket is is a 4-inch sport-scale model of the Honest John 1B. The 1A, with the giant triangular fins, is more commonly modelled, but I prefer the look of the 1B.

This rocket was printed using PETG in an Army green color. The main feature was how I printed wraps to finish the body instead of painting. Not only did this avoid the mess of painting, but it made sure the body matched the color of the printed parts.

The Pictures

The Design

My build uses mostly 3D printed parts, except that I still prefer standard phenolic body and motor mount tubes in most cases. However, using standard body tubes means filling spirals, priming, sanding, and painting. I didn't want to do that, so I came up with the idea of trying printed wraps, which turned out pretty well.

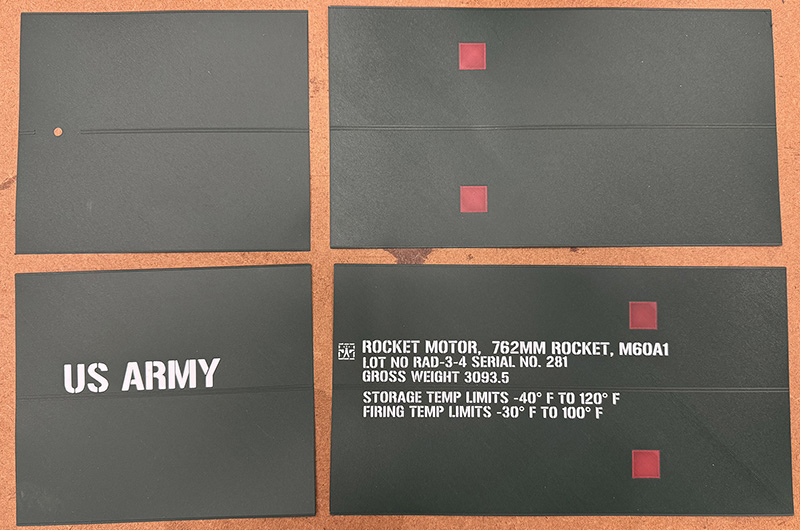

Of course, I couldn't print the wrap as a single part, so I split it into four pieces. There were longitudinal panel lines on the prototype, which I could take advantage of for the front/back split. However, there weren't panel lines that would camoflague the forward/aft split. In retrospect, I should have invented panel lines there to make it look more intentional.

My first attempt was a single filament layer using a 0.4mm nozzle. That worked, but was cruder than I like and so had some small holes at the corner of lettering. The final wraps were printed with the finest possible settings using a 0.2mm nozzle with 3 layers. The bottom layer was all the background color (green) and the white lettering and red squares were 2 layers thick. Using the minimum layer height, this made the wraps still flexible enough for a 4"e; tube and opaque.

In case anyone wants to do something similar, here are the printed parts:

- nose base

- nose mid

- nose tip

- fin can

- forward CR

- ebay gasket

- ebay insert

- ebay ring

- wrap back aft

- wrap back fwd

- wrap front aft

- wrap front fwd

Or one zip file of them all. Or you can download them from Thingiverse.

The CR and ebay were printed in PLA-CF, the body sections in PETG and the gasket in TPU. I always use gyroid infill with the CRs and fin can at 50% to maximize strength and the body parts at 15% to reduce weight.

The wrap is split into four pieces. the front and back along panel lines that exist in the prototype. The lettering is very slightly taller, enough to paint with color in the slicer, but not enough to print taller.