Bulkhead Tests

This project has been on hold for quite a while and is something I may or may not get back to in future.

The most common material for building bulkheads for high-power rocketry (HPR) is plywood, with the high-quality ("birch" or "aircraft") plywoods being preferred. These plywoods have very few or no voids and more plies than standard "shop" plywood. Plywood is itself a composite material, made of thin layers of wood glued together. Each layer is aligned at a right angle to the adjacent ones. They are generally made with an odd number of plies so that both external surfaces have the grain running in the same direction. For example, the commonly-used ½" birch plywood has 9 plies.

Plywood works well, but it is heavy and it still breaks under exceptional recovery stresses. This article investigates other composite materials in addition to plywood. I will be making home-made composite bulkheads using various core materials and reinforcements. All my bulkheads will be bonded with epoxy (West System 105/205).

Materials and Construction

Core materials do add some strength, but are primarily used to keep the reinforcement layers separated. For my tests, I have concentrated on light core materials (balsa and Rohacell®) and expect most of the strength to come from the reinforcement material. In order to achieve this, I am going all-out and choosing the optimal reinforcements:

- 5oz. cloth made with Kevlar®* for strength on the hardware side of the bulkhead,

- 6oz. carbon cloth fiber for stiffness in the sandwich and

- 6oz. S-glass cloth for general strength in the sandwich and for surfacing.

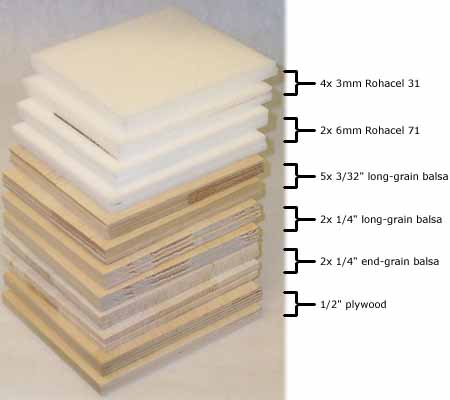

I am trying a new core material as well: two kinds of Rohacel. Rohacel is a brand name for closed-cell foam, which comes in sheets. It is easy to cut with a rotary cutter and completely uniform. It comes in several densities and I am trying two of them: 31 and 71. The 4-ply bulkheads use the 3mm 31 Rohacel and the 2-ply bulkheads use 6mm 71 Rohacel.

I am also trying familiar balsa wood as a core material. This strong and light weight wood makes an excellent core material and is very cheap and easy to obtain. You can find sheets of various widths and thicknesses at your local hobby shop in the model airplane section. I'll be using two thicknesses of long-grain balsa: 3/32" (5 plies) and ¼" (two plies) and also ¼" (2 plies) end-grain balsa.

| 3mm Rohacel 31 vs. 6mm 71: | long- vs. end-grain balsa (both ¼"): | |

|

|

That makes a total of five core materials to test:

- 3mm Rohacel 31 (4 ply)

- 6mm Rohacel 71 (2 ply)

- 3/32" long-grain balsa (5 ply)

- ¼" long-grain balsa (2 ply)

- ¼" end-grain balsa (2 ply)

(Plus, of course, the ½" plywood as the control.)

To start with, I've cut out the core materials into 6" square blanks. Note that I decided to make two of each bulkhead, which means making a total of ten composite bulkheads! You can see the core materials stacked up in the picture below, including the two pieces of ½" plywood on the bottom.

Next, I cut the reinforcements made from Kevlar®, carbon fiber and fiberglass. Note that all pieces were cut to 7" squares for ease of handling. I cut half the pieces on a 45° bias so that fibers would run in four directions in the completed piece. This is an extra bit of work which is probably not necessary, but I wanted to use "best practices" when building these bulkheads.

Below, you can see the weighing of the reinforcement. To try to get as accurate a weight as possible, all reinforcements of the same material were weighted at the same time and then the total was divided by the number. Note that the pieces cut on a 45° bias are offset from the square-cut pieces.

This turned out to involve more work than I'd planned on. Below you can see the parts laid out for a single bulkhead (Test 1, the 3mm Rohacel). That's four pieces of Rohacel core, four pieces of fiberglass, two pieces of carbon fiber and one piece of cloth made from Kevlar®. (On the lower left is the base board and bottom breather and release.)

In Table 1 below, you can see the weights for the dry materials (core and reinforcement) for all five bulkhead tests. Note that these are all oversize at this point; 6" square core blanks and 7" square reinforcement pieces.

| Test | Core Material | Individual Weights | Total Weight | |

|---|---|---|---|---|

| 0 | ½" plywood | n/a | 186.5g | |

| 1 | 3mm Rohacel 31 | 4x 3mm Rohacel 31 | 8.6g | 51.9g |

| 4x fiberglass | 25.2g | |||

| 2x carbon fiber | 12.8g | |||

| 1x Kevlar® | 5.3g | |||

| 2 | 6mm Rohacel 71 | 2x 6mm Rohacel 71 | 24.5g | 55.2g |

| 2x fiberglass | 12.6g | |||

| 2x carbon fiber | 12.8g | |||

| 1x Kevlar® | 5.3g | |||

| 3 | 3/32" long-grain balsa | 5x 3/32" balsa sheet | 41.5g | 91.2g |

| 4x fiberglass | 25.2g | |||

| 3x carbon fiber | 19.2g | |||

| 1x Kevlar® | 5.3g | |||

| 4 | ¼" long-grain balsa | 2x ¼" long-grain balsa | 35.7g | 66.4g |

| 2x fiberglass | 12.6g | |||

| 2x carbon fiber | 12.8g | |||

| 1x Kevlar® | 5.3g | |||

| 5 | ¼" end-grain balsa | 2x ¼" end-grain balsa | 45.6g | 76.3g |

| 2x fiberglass | 12.6g | |||

| 2x carbon fiber | 12.8g | |||

| 1x Kevlar® | 5.3g | |||

Several interesting things jump out from this table. The balsa is a lot heavier than the Rohacel, even the Rohacel 71. Secondly, the reinforcements are heavier than the core materials; the higher-ply balsa sandwiches are heavier than their lower-ply counterparts, which shows that the reinforcement is denser than the balsa core. Thirdly, the Rohacel 31 is a lot lighter than the 71 (8.6g vs. 24.5g). Lastly, the end-grain balsa is heavier than the long-grain balsa (45.6g vs. 35.7g), which is partly due to the glue and backing material used in the end-grain core sheets.

| Test | Core Material | Material Wgt. | Epoxy Weight | Total Weight |

|---|---|---|---|---|

| 0 | ½" plywood | n/a | 186.5g | |

| 1 | 3mm Rohacel 31 | 51.9g | g | g |

| 2 | 6mm Rohacel 71 | 55.2g | g | g |

| 3 | 3/32" long-grain balsa | 91.2g | g | g |

| 4 | ¼" long-grain balsa | 66.4g | g | g |

| 5 | ¼" end-grain balsa | 76.3g | g | g |

Strength Test

Results

* KEVLAR® is a trademark of E.I. du Pont de Nemours and Company.