Boosted Arcas

In November 2015, MAC Performance introduced their kit of the ever-popular Arcas sounding rocket. However, without the boat tail, it looked more like sustainer of a 2-stage version which gave me the idea of using it as a basis for modeling the "Boosted Arcas."

The prototype was 4.5" O.D. and I decided to model this using 3" tubing (3.15" OD), making this a 70% scale model.

I didn't end up using the MAC Performance Arcas kit since I already had the parts, but their kit is very close and would make a good option for the sustainer. I did decide to build the sustainer with their 3" canvas phenolic tubing and the interstage with their 3/16" phenolic plate.

The Pictures

|

|

The rocket was finally completed in June 2018, after a long hiatus. I had lost my paint booth in the shop move so the finish wasn't as good as I'd managed before. I've also lost the green backyard for rocket photos, so you see it above against the much more prosaic roll-up door.

The Design

After selection of the body tube size (standard 3.0" tubing), the next job was to make a dimensioned drawing of the rocket to be built. This turned out to be harder than just scaling dimensions from a complete set of plans because I couldn't find one.

Eventually I found drawing with most dimensions marked and was able to take a shot at the others by scaling them from the drawing itself (see the Historical Info section below) and produced my overall drawing.

Once again the interstage was an open truss structure. (I seem to keep making these lately, first for the Aerobee and then for the Iris). This time I decided to use phenolic for the plates, rather than aluminum, since I was building use MAC Performance canvas phenolic tubing.

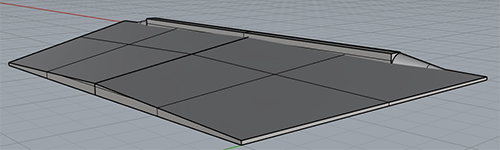

Built-up fins are a key part of many sport-scale rockets and I'd used lots of different techniques to make the profiles in the past. This time, I decided to use 3D-printing, which is a lot easier than other fabrication techniques and allows more detail.

Construction

There are two main parts of this rocket: the sustainer and the booster + interstage. The sustainer is straight-forward, except for arrangements for sustainer motor ignition and coupling to the interstage. The booster is also straight-forward, making the interstage the most interesting part.

Interstage

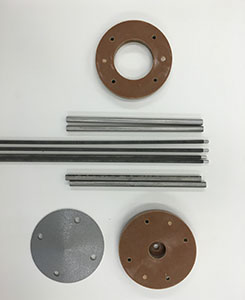

The prototype interstage is quite long for the diameter. My 70% model interstage is 6¾" overall with 6" rods plus an aft and forward end plate. Each plate is made from two ³⁄₁₆" thick canvas phenolic plate cut differently and then bonded together.

Above you can see the five rings cut out. (The smaller-diameter ring on the bottom left fits into the electronics bay in the booster, so doesn't add to the interstage length.) The top row is the forward end and the lower row is the aft end.

In order to keep them aligned during glue-up, I drilled ⅛" holes in all pieces, so a dowel could keep them in registration. Above you can see the two assemblies curing.

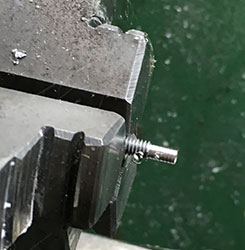

In this rocket, the struts are arranged between the fins rather than in line with them, so I decided to use the threaded rod ends as pins for coupling to the sustainer aft end. To make this work, I used #8 threaded rod and turned down the ends to ⅛" diameter pins. (I don't have a metal lathe so I recruited a friend to help; thanks Tom Rouse!)

|

|

Above left you can see one of the rods in the lathe chuck and above right you can see the four rods with ¼" of the end turned down and slightly chamfered. #8 threaded rod is marginal for clean ⅛" diameter pins, but I wanted to use ¼" tubing and these rods are a good fit inside it.

These pins socket into the aft end of the sustainer and still can be bolted at both ends to hold the interstage together.

|

|

The individual pieces above left and dry-fit of the interstage assembly on the right. Below you can see the aft end on the left and the forward end with pins on the right.

|

|

And finally the coupler-coupler avionics bay slips over the reduced-diameter ring at the aft end, completing the interstage and booster bay.

This was the trickiest part of the rocket, and the most fun to design, so it was completed first.

Booster

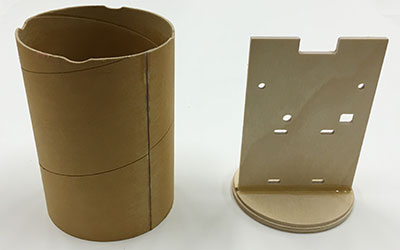

The booster is just a short rocket. The only real complication is that the prototype narrowed in the middle, so to simulate that I used a 3" coupler tube full length with sections of body tube at the ends.

The sustainer is all MAC Performance canvas phenolic, but I needed a full-length coupler so I used some Giant Leap phenolic I had laying around. (See my Body Tubes article for more info.)

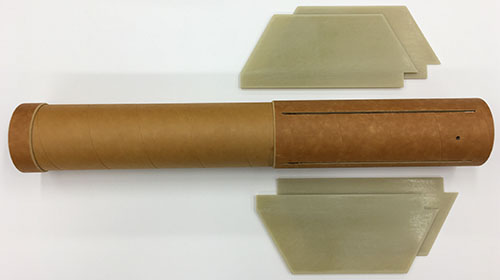

Above you can see the airframe parts for the booster. The coupler has a short piece of airframe at the forward end and a longer piece for the fin can. The MMT is a 10" long 38mm tube, leaving adequate room for recovery.

Of course, since the body of the booster is a coupler, I needed a coupler to fit inside a coupler for the avionics bay at the forward end. I made a video on how to Make a Coupler to demonstrate the process.

Above you can see the coupler section and the small avionics bay to accomodate a Missile Works RRC2+. This is the smallest unit I had on hand and I wanted to keep the bay short to leave room for the recovery system.

This avionics bay is actually part of the interstage, which acts as the "nose cone" for the booster. It won't go very high and doesn't weigh much so single deployment and a small 'chute will be sufficient.

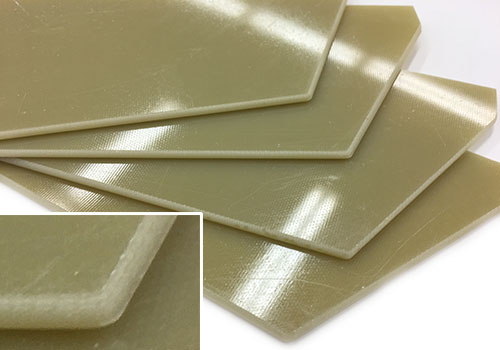

I couldn't find any details about the fins on the booster of the Boosted Arcas, so I modeled them from flat ⅛" G-10 sheet with rounded edges. (They probably had a more interesting profile in the prototype, but oh well.)

I decided to try rounding over the edges of the booster fins using a router bit, and I actually found one with a 1/16" radius and a pilot bearing. I had tape a piece of plywood the same shape for the bearing to run against, but otherwise this was a straight-forward edge routing operation.

After the edge treatment, the fins were ready to mount. I sanded both surfaces with 120 grit sandpaper and the root area with 100 grit to provide roughness for a good epoxy bond (inside and outside fillets).

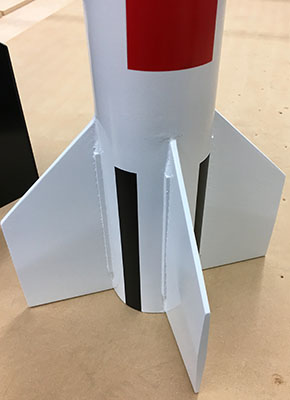

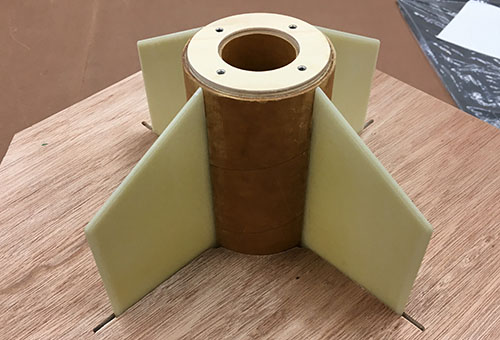

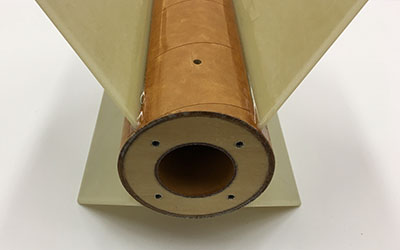

Finally, all four fins were mounted with epoxy along the root edge and held in alignment using a standard fin guide. The fins also fit tightly in the slots so everything is maintained in alignment while the initial epoxy bond cures. (The after centering ring is just set in place, but not bonded, to ensure the MMT remains centered.)

The standard interior and exterior fillets completed fin attachment. I don't build many rockets with four fins, and the extra work is definitely noticeable. After all that the aft centering ring mounted flush with the aft end of the body tubes.

"Tubes" plural because the inner coupler tube is full length and the body tube on the aft section doubles it. To finish off the aft end, I laminated a layer of 4oz fiberglass to seal the MMT, centering ring and body tubes.

The final piece is the motor retainer, which I cut out of 0.100" aluminum and had black anodized. (The booster will be painted black so the retainer and screws will blend in.)

Sustainer

The sustainer is a straight-forward rocket. The Boosted Arcas didn't have a boat tail, presumably to better couple with the interstage, so there isn't even the normal Arcas aft-end complexity. The other difference is that the fins are a different shape from the normal Arcas, with a longer root chord.

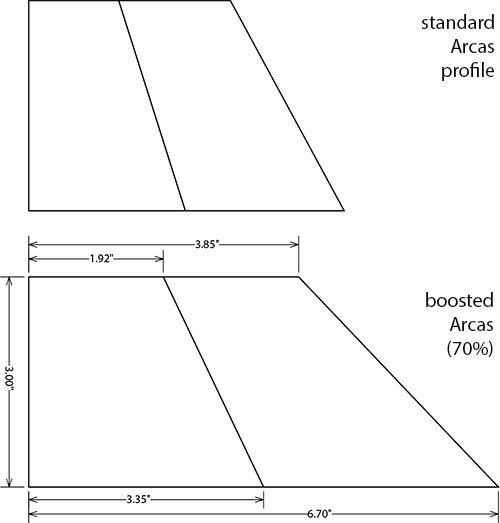

Above you can see a comparison of the lengthened fins to the standard Arcas profile. I decided to maintain the profile shape for interest, although it's difficult to determine what it's supposed to be from the photos I found (see Historical Info. below).

And finally the drawing of a half-profile one for each side of the fin cores. This will end up being ¼" (6.4mm) thick between the core and two profiles, providing a dramatic shape.

The tubes for the sustainer are plain 3" canvas phenolic and the the nose is a Rocketry Warehouse fiberglass ogive. Most of the drawings show what looks like a cone, but the photos show a pointed nose with a definite curve; see below. The sustainer also uses a 38mm MMT (anything larger would interfere with the interstage), but this one is 22" long as there is plenty of space.

The electronics bay is in the coupler between the aft and forward airframe sections. A 3" tube doesn't give much space, but it's plenty for a G-Wiz LCX which can handle both the sustainer ignition and dual deployment.

The fin cores are 1/16" carbon fiber plate for stiffness, and most of the thickness comes from the cosmetic profiles describe above.

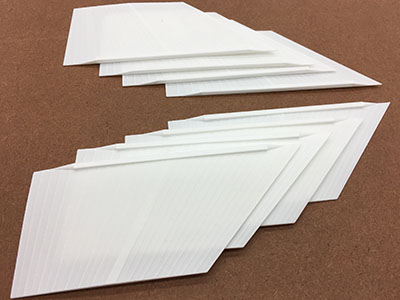

I printed out the profiles using Shapeways, eight pieces with two sides per fin. As usual, they did a good job on the details although I was surprised by the ridges on the surfaces, which required a lot of filling to make smooth. Perhaps shallow slopes are difficult for this process (SLS Nylon).

The profiles were bonded to each side of the cores with epoxy.

It's always fun to take advantage of something unexpected, such as the clothespins seen above. These keep the profile pressed against the core while the epoxy dries without out deforming it.

Bonding the fins to the airframe was completed in the usual way, and the aft end of the sustainer was capped with an aluminum plate. If you look carefully, you can see the holes for the pins in the interstage and another hole for the igniter wire.

![]()

At LDRS 38, I purchased one of the new Featherweight GPS trackers, so I decided to use that in this rocket. This tiny unit fit easily into the nose cone.

Historical Info.

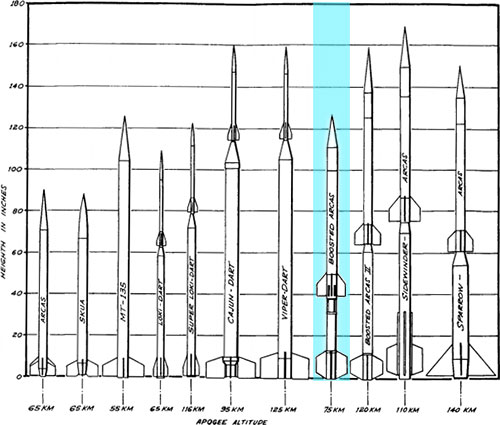

The information below comes from NASA Contractor Report CR1529 Part 2, "A study of 30km to 200km meteorological rocket sounding systems." This was particularly interesting because it puts the different sounding rockets into context:

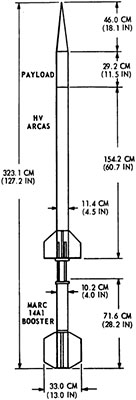

The key finding was the drawing on page 312 of the report (328 of the PDF). Also interesting were the specs before and after the drawing.

|

|

Above left is a photo of the Boosted Arcas in flight and above right is the dimension drawing from the NASA report.

There are various versions of the boosted Arcas in limited use today as indicatd in table 6-20. The Arcas is used as a second stage in this configurations and the payload capacity is as follows:

| Payload Weight | 10-30 lb |

| Payload Diameter | 4.25 in |

| Payload Lenght, Nominal | 26 in |

| Payload Volume, Nominal | 305 in |

The performance of the boosted Arcas vehicles depends upon the booster used. A brief description of each of the boosted Arcas configurations is presented in paragraphs which follow.

The booster is an Atlantic Research 0,8-KS-2700 rocket motor. Power for ignition of both stages is provided by a ground source, a motion switch firing the sustainer igniter after positive ignition. An optional sustainer igniter incorporating a 2-second delay is also available. Fin assemblies are preset to provide a roll rate of approximately 25 rps at burnout.

The vehicle is launched from the standard ARCAS rocket launcher with the breech door open. Assembly and launch preparation requires no special handling equipment and can be accomplished by a two-man crew.

First-Stage Motor

| MARC 14A1 | |

| Nominal performance rating | 0.8-KS-2700 |

| Principal diameter | 10.2 cm (4.0 in) |

| Overall length | 71.6 cm (28.2 in) |

| Igniter Type | Pyrotechnic |

| Recommend firing current | 3.5-5 amp |

Second-Stage Motor

| MARC 2B1 ARCAS | |

| Nominal performance rating | 29-KS-324 |

| Principal Diameter | 11.4 cm (4.5 in) |

| Overall length | 154.2 cm (60.7 in) |

| Igniter Type: | Pyrotechnic |

| Recommended firing current | 5 amp |

Weights (less payload)

| Gross launch weight | 46.3 kg (102.0 lb) |

| First-stage burnout | 41.3 kg (91.0 lb) |

| Second-stage ignition | 30.1 kg (66.4 lb) |

| Second-stage burnout | 10.6 kg (23.3 lb) |

The entire report can be downloaded from the NASA archive: NASA Contractor Report CR1529 Part 2.

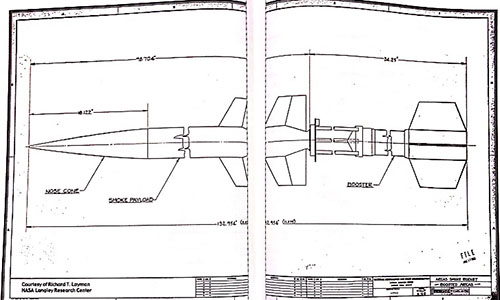

Marcus Harmon scanned a double-page drawing from Small Sounding Rockets (now out of print), which has some more detail (although for a different arrangement than I'm planning to model).

This gives a better view of the booster, showing the changes in diameter and that there is a small cone on the forward end.

There's nothing in particular on the Boosted Arcas in Rockets of the World, my usual go-to reference. But there is one page (136 of the Third Edition) on the Sparrow-HV Arcas that appears to have the same aft end as the Boosted Arcas.