Printed Epoxy Bonding

Long ago, I made a short video on how well fiberglass/epoxy sticks to PLA 3D printed parts. The answer is "reasonably well." Since then, I've gained a lot more experience with 3D printing and have been saying "epoxy bonds well to ABS and Nylon, but less well to PETG."

After the rigorous testing of printed component strength, I felt like it was time to prove out that conventional wisdom. After all, it's one thing to replace traditional components with 3D printed ones, but we sometimes still need to bond them to dislike materials, for which the traditional adhesive is epoxy.

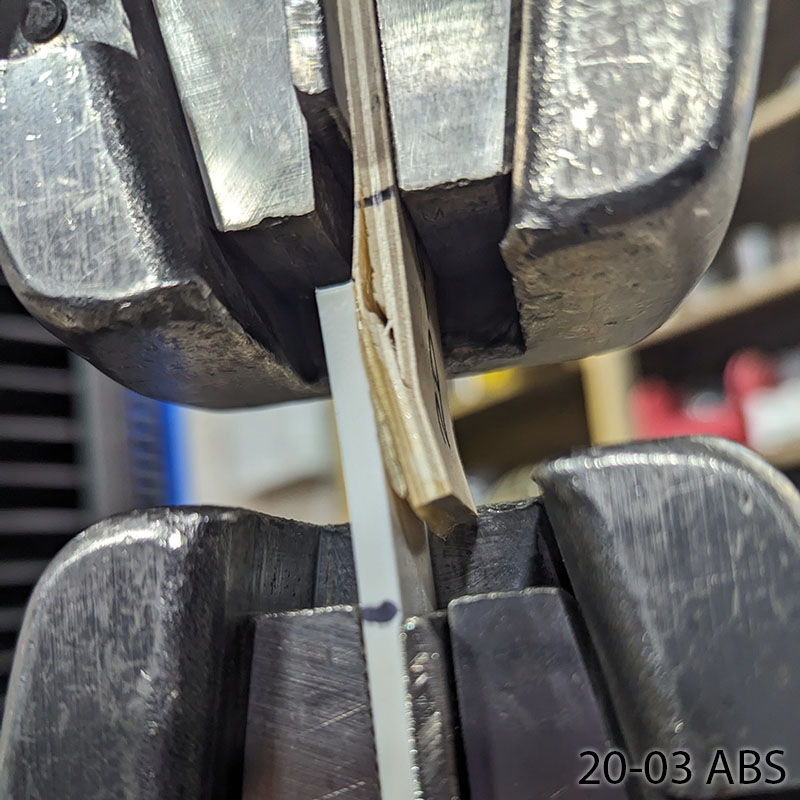

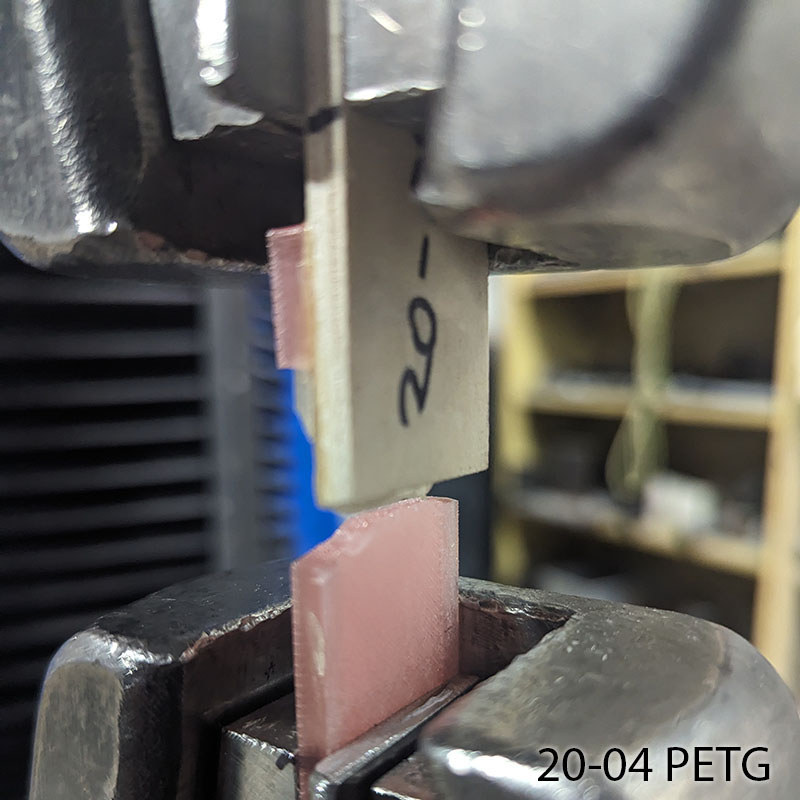

Anyway, it appears to me that all four types of filament can be effectively bonded will with epoxy. Upon reflection, this makes sense since we're really just creating a mechanical bond. In fact, ABS was the only material where the joint may have failed before the parts!

See the detailed results.

Test Setup

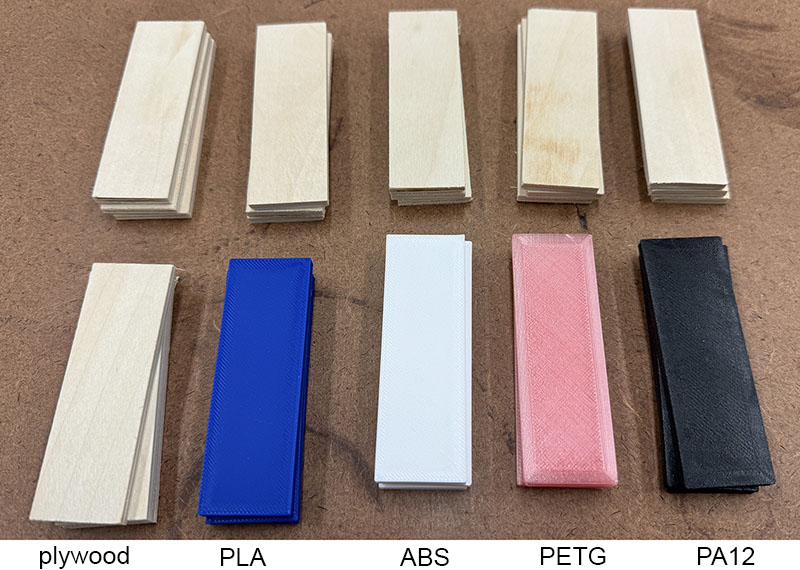

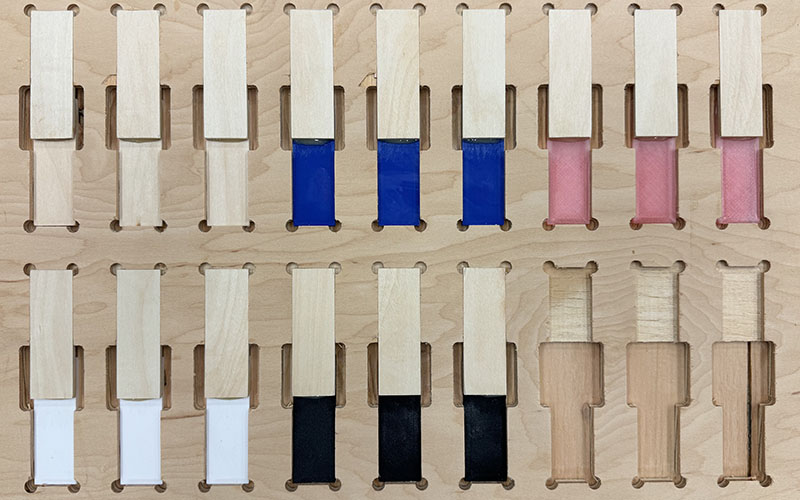

I decided to use a standard lap-shear test, with the parts 25mm wide and with a 25mm square bonded area. The filaments tested were: PLA, ABS, PETG and Nylon (PA12), as well as a wood/wood sample as a baseline. Here are the individual parts printed/cut:

All samples were 4mm thick, with the 3D printed samples using the settings I determined to have maximum strenth when testing centering rings. The bonded surfaces were lightly sanded with 100 grit sandpaper to provide roughness for the epoxy.

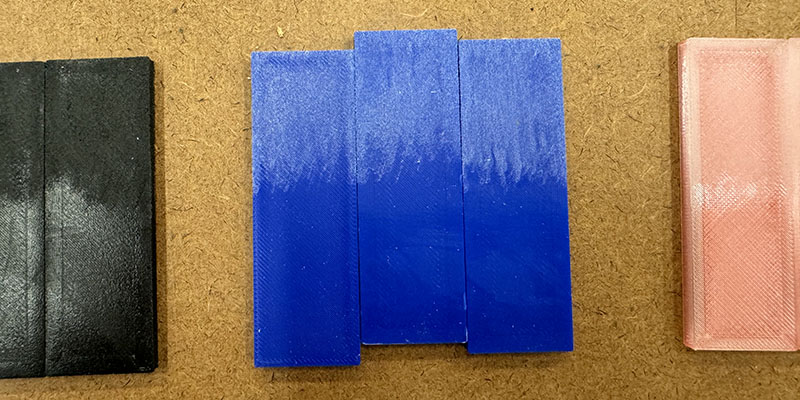

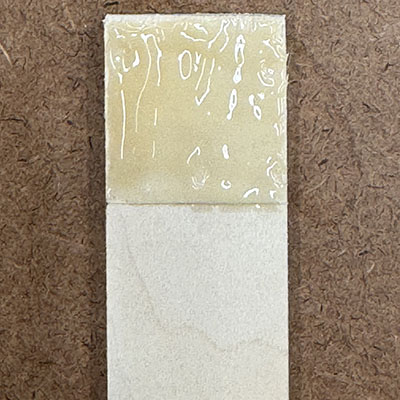

A thin even layer of Aeropoxy ES6209 was painted on one piece for each pair on the overlap area.

Each sample was bonded in a tray to hold them in place so that they were as uniform as possible.

Once the epoxy was cured, the samples were numbered and removed from the tray.

Then it was time to send them off to the lab.

Test Results